This is a contest to judge whose program controls logistics robots best.

The contestants use the real data from real distribution centers which Daiwa House Group operates.

The contest has made available to the contestants the layout data of a warehouse based on the real warehouse of logistics facility of ICLP, inventory information of the stocked goods, and their delivery and reception instruction data of the real warehouse. Future distribution centers employ many logistics robots. The contest calls for programs which can manage and control such robots intelligently using the available data.

The 'intelligence, ' which was the major factor for the contest qualification includes the accuracy of handling the outgoing shipment and reception instructions, and we have added to it the optimization of either ① the delivering as quickly as possible, or ② the efficient robot movement.

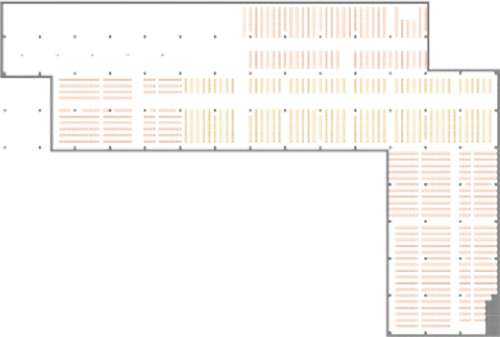

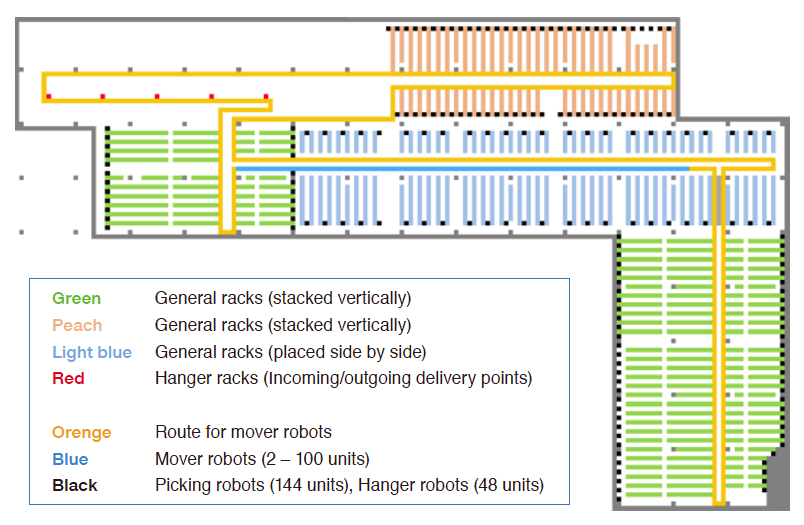

The warehouse which is the subject of the contest has the layout in the figure. The floor is divided by grids, and the following two types of racks occupy the floor space.

There are multiple types of robots employed at the warehouse.

Mover robots move goods from one point to another. They can carry five goods at the maximum simultaneously.

Picking robots and hanger robots can put/take goods into/from the racks. They can take out goods from a rack and placed them on the mover robots, or store goods from mover robots to a rack.

These mover robots, picking robots, and hanger robots can move along the grids of the warehouse. They have to be returned to the same starting position at the end of the day for recharging. In addition to the above robots, there are dedicated robots for the reception and outgoing shipment points.

The major function of the program to be developed for the contest is to issue instructions to the robots in the warehouse so that the operation of the warehouse proceeds appropriately. For example, when there is an instruction for reception, the goods need to be received from the reception robot, and they need to be transported to a rack by a mover robot, and they need to be stored in a rack by either a picking robot or a hanger robot. When there is an instruction for outgoing shipment, goods need to be taken from a rack by either a picking robot or a hanger robot, and they need to be transported to an outgoing shipment point by a mover robot and then they need to be passed to the outgoing shipment robot.

The contest this time requests the submission of a program that can digest the real world data for a week and behave in the following manner.

The contest has made available a simulator that mimics the behavior of warehouse and robots based on a program control. Simulator can be controlled by exchanging data with a submitted program via the standard input/output and we can judge the quality of the control performed by the program.

In the final judgement, each submitted program was evaluated by running the program against hitherto unpublished week-long data of reception and outgoing shipments. We measured the following numbers.

For the following numbers, we wanted each program to achieve 100% success rate as much as possible.

We requested one of the following numbers to be minimized.

The contest used these numbers and looked at the approaches taken by the contestants to select the prize winners after a rigorous and fair discussion in the judge meeting.

This “Logistics Robot Programming Contest” called for programs to control virtual picking robots in an optimal manner based on the real warehouse layout and real data on incoming and outgoing deliveries. The contest requires higher programming skills compared to the previous contests that only provided data to be utilized. If you can create a control program that can operate in the simulated real world, you definitely have considerable programming skills.

I conclude that the final evaluation factor turned out to be the strategy , that is, the basic concept on warehouse management that is higher than simple algorithms after reviewing the submissions and grading them. Now, this contest was more challenging in the sense that contestants had to seek and formalize additional problems by themselves before meeting the basic requirement. Needless to say, submissions were expected to achieve 100% success rate of incoming/outgoing deliveries as much as possible. And then, contestants needed to think about how to control the balance of the multiple evaluation criteria such as shipping speed and energy efficiency, how to assign their priorities, and what conditions to assume.

For example, among the three prize winners , “swarm” came in first and “kurukuru” came in second in shipping speed and shipping success rate. “robot_solver” ranked number one in energy efficiency. “kurukuru” is highly responsive, but not energy efficient because many robots go the rounds along the route, and it uses outstandingly many robots. “robot_solver” uses the minimum number of robots and ranked the best in energy efficiency by placing a limited number of mover and picking robots in charge in each area. However, it did not receive high grade marks in shipping speed and success rate of incoming/outgoing deliveries. Thus, multiple evaluation criteria have a trade-off relationship, and it is difficult to satisfy the criteria in a balanced manner.

In an extreme example, to create the best program in shipping speed, all you need to do is use a large number of robots and make them not block other’s route. However, robots cost a lot, and it may not be possible to use them as many as you want. On the other hand, in some cases, you may increase shipping speed by adding only a few more robots you can afford. ― If the number of robots is fixed in the contest where contestants compete in shipping speed, there will not be a room for such strategic adjustments. The contest will not be interesting unless we have the option of making strategic trade-off decisions that affect real business.

“swarm,” which won the Grand Award, ranked the best in shipping speed and success rate. It uses more robots than “robot_solver” and fewer than “kurukuru,” and has moderate energy efficiency. We thought highly of the design of “swarm” and it is best suited to meet the goal of quick deliveries among the submissions. Its strategy assumes that robots work together autonomously instead of top-down control. We also viewed as very modern its approach of distributing a large number of items in different places quasirandomly to avoid the contention of robots. It costs human to share the knowledge on “what is located where.” So, it makes sense to have the same items gathered in certain area for smooth outgoing delivery as much as possible. However, computers do not mind if same items are placed in random locations, and they can share the knowledge by cooperating with each other on network constantly. In this way, “swarm” challenges the “common sense” of human workers in the first place to solve the posed problem and it meets the goal of this contest very well. So “swarm” won the Grand Award.

Daiwa House Industry Co., Ltd. of Daiwa House Group has been deploying “D Project,” a development scheme of distribution facilities throughout Japan. Currently, 180 facilities are in operation, and 57 more facilities are being planned.

We have felt that development and construction of distribution facilities alone are incomplete and insufficient to reduce the overall distribution cost of our tenants. Therefore, Daiwa LogiTech inc., a holding company, was established in November 2017 as a provider of solutions to the cost problem by affiliating the following companies;

Frameworx, Inc. with Intelligent Logistics Center Management System that enables flexible cooperation among WMS, robots and censors, Hacobu Co., Ltd., with “MOVO,” a system to perform cloud-based car dispatch and operation of cars, acca international Co., Ltd. with “ALIS,” a system to handle necessary operations for electronic commerce (EC) such as shooting photos of products, measurement of physical factors, input of product description manuscript, customer support, etc.

Ground Inc. with “Butler,” an automatic delivery robot.

In the contest , the real data of these companies were provided. There are many good submissions to the contest, so we, judges, had a hard time selecting the following three prize winners. As Chief Judge Sakamura mentioned, we evaluated the submissions based on “Shipping speed,” “Energy efficiency” and “Success rate.” The best program for each criterion is as follows.

The Grand Award has been awarded to “swarm” by Hiroshi Hanano considering various factors including its approach. The Excellence Awards winners are both excellent for their approaches, creativity and the priority of the criteria 1 to 3 above and it was impossible to say either is better than the other. In the next contest, judges will evaluate submitted works with the fourth criterion ‘the number of robots.’ That is, we would like to evaluate submissions in terms of initial and running costs. We may change the priorities of criteria, too. I would like to express our gratitude to the efforts of all the applicants including the award winners, and we would like to work together to develop the submissions for business use.

Mr. Hanano , Mr. Arakawa and Mr. Inoue , congratulations on the award. And thank you, all the participants for taking time from your busy schedule. We would like to continue this contest next year and the beyond, and look forward to your participation and working together to use your ideas for business in the future. We need your wisdom for the evolution of logistics. Thank you for your continued support for Daiwa House Group.

I would like to express my sincere gratitude to all the applicants who have taken an interest and participated in this logistics contest, and I would like to thank those who supported the Logistics Robot Programming Contest. It has been held successfully.

We have been holding the contests since 2016 by making available the data related to logistics and calling for its utilization. This is the third one. We are pleased to keep holding the contest where we can always learn and discover something new.

At the judge meeting, judges including myself were really impressed by the concept of some programs. For this contest, the real data generated at Intelligent Logistics Center operated by Daiwa House Group was provided. This probably has made it difficult for contestants to develop their programs. The judges reviewed the operation results of the simulation carefully since the proposed programs and usage directly affect our business and operation. We appreciate the efforts of the award winners who overcame these difficulties.

For example, “swarm,” which won the Grand Award, produces a very high success rate, and uses a modern approach. I would like to see it developed for business use.

To my regret, I feel there are at least three points that need to be improved toward the next contest;

In addition, we would like to plan a visit by the contestants to actual logistic facilities and have a discussion on the spot if possible. That may make people more interested in distribution/logistics. We would like to realize these in the future.

With the shortages of human resources, people have become aware that “distribution/logistics” is the key element of management strategy. It has also been clear that “data” utilization is essential element for business management. As we often hear the phrase, digital transformation, attention of enterprises has been focused on artificial intelligence (AI), robot and digital (data) utilization for business. We hope to keep holding this contest with possible alternation of forms to provide tips for the solutions to digital transformation.

We look forward to your continued interest and participation in the future.

This is my first time to be a judge of this contest. As the required task of the contest is very high, I wondered if anyone wants to participate in the contest at all to tackle the challenging requirement. So, I was surprised to find many submissions. Among them, the technical quality of the submissions of the award winners is especially high. I think we can commercialize these programs as real world applications after some improvement.

At the judging meeting, the major evaluation criterion was “success rate.” Quantitative values such as “shipping speed” and “energy efficiency” were also evaluated as well as qualitative perspective such as novelty of “idea.” The important point of this contest is that it was required to create programs that handle the real data generated at the real logistics center. Whether the number of the incoming and outgoing deliveries recorded at the warehouses can be processed by the submitted programs in actual working hours is important. That is the “success rate.” Programs with high “success rate” can work well at real world sites. In terms of “success rate,” the best program is “swarm” created by Mr. Hanano, the Grand Award winner. The other two prize-winning programs, “kurukuru” by Mr. Arakawa and “robot_solver” by Mr. Inoue also produce high rate of success. The reasons why “swarm” drew the attention of the judges most are not only the good quantitative values such as “success rate,” “shipping speed” and “energy efficiency” but also its “idea.” With this program, robots work together autonomously without overall control. That was evaluated as a very creative approach.

In the logistics industry, the environment in which traditional analog information becomes available as digital data is about to be realized. Through the works

of prize winners of this contest, I learned that many talented people can put collected digital data into clever algorithms, so I am sure of the bright future of logistics. I had a very productive and meaningful time as a judge during this contest. Thank you.

swarm is a program that makes “many robots work together in a warehouse without frequent and detailed instructions.”

There are three key ideas that guided the development.

First, assign tasks to the robots properly. It is necessary to give higher priority to incoming deliveries than to outgoing deliveries to avoid stock out, for example.

To avoid congestion, we assign tasks incorporating stochastic conditions, so that robots will not be stuck trying to do the same task.

Second, make the robots work together. If the robots work as they like, they may disturb the operation of other robots often. With swarm, the robots talk to each other to decide who comes first to work instead of being controlled globally by the program. For example, the robots which take out items should not be disturbed and left alone to finish the operation, and the robots not at work go elsewhere temporarily to avoid congestion.

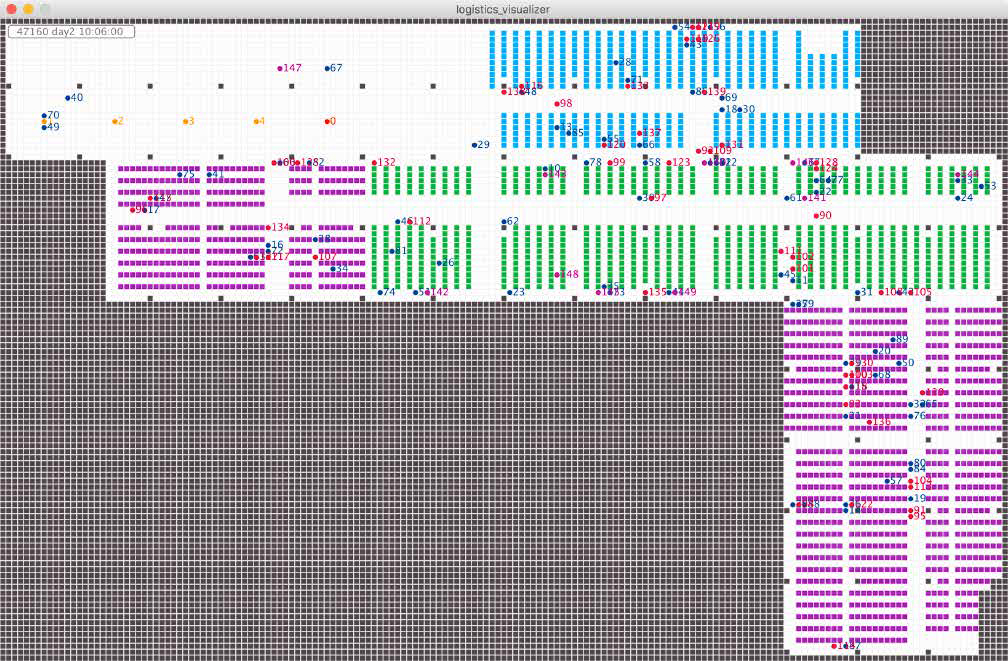

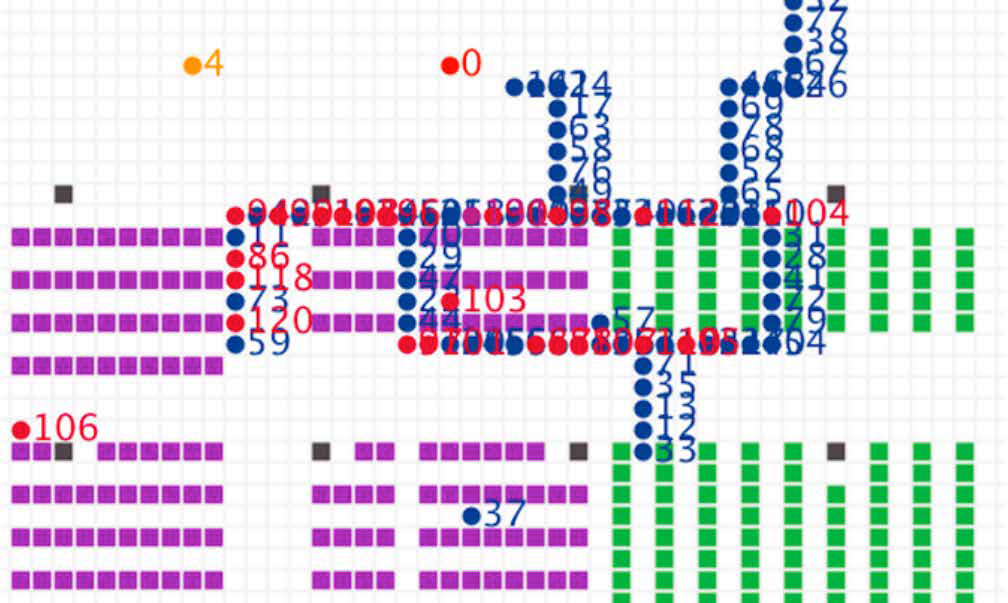

Third, observe how the robots behave carefully. Programs which “ought to work efficiently on paper” may not work well in the real world. I noticed many inefficient behaviors of the robots by creating visualization software and observing the behavior of robots. I thought it was better to put popular items on the shelves near the exit for better efficiency. However, many robots gathered in front of the selves and were stuck. (Figure 2) So I learned that popular items need to be distributed in different locations in the warehouse to some extent.

Figure 1. Visualization software

Figure 2. Robots were stuck in front of the shelves of the popular items

When I developed this program, I focused on avoiding the collisions of robots. Many robots move around in the warehouse to carry many items for quick incoming and outgoing deliveries, so it is not easy to avoid a collision. I decided to create a one-way single route in the warehouse as shown in the following figure, and mover robots go the rounds along the route. In this way, mover robots do not collide with other robots unless they bump into the robot in front of them.

Mover robots go into the rows between the racks only when storing and taking out items are needed. Picking robots and hanger robots which load and unload items are placed in each row, and move to a target rack according to the timing of the mover robots. Mover robots handle incoming and outgoing deliveries when they approach the points of deliveries.

Then number of the mover robots can be selected between two and 100. It takes more time to perform incoming and outgoing deliveries if less than optional number of mover robots are used. If too many robots are used, though, they incur wasted movement. After simulations using different number of mover robots, I chose the proper number of the mover robots.

The theme of this contest was clear and simple, and required us only to think about “carrying items in the warehouse.” However, it has very profound meanings. If I want to create more efficient algorithms, I definitely need more time.

Before working on energy saving and reduction of the delivery time, it was difficult for me to write a program that makes robots carry items smoothly. If many robots running in the narrow corridor between the shelves are controlled without much care, they may bump into each other and be stuck.

In such a case, the one of the robots needs to yield and take another route. However, the robot may not be able to take another route if there is a pillar on the route, or may bump into another robot after avoiding the first one.

In robot-solver, the warehouse is divided into about 30 areas, and each area has only a mover robot and a picking robot. This way the robots do not bump into each other.

If a mover robot is about to bump into another robot outside the area, one of them yields to

proceed along a new route.

I completed my program barely in time. I know I could do better, and I have many more ideas I wanted to try if I had more time.

I had a valuable experience to create a program for business use by using large scale drawings of the real-world objects for the first time.

I would like to participate in the next contest definitely.